GUANGDONG GUANHONG INTELLIGENT EQUIPMENT CO.,LTD.

Booth Number: Hall 13.1 - 13.1E17

Add GPAC Wechat for consultation

Share this page

Exhibitor E-invitation

Invitation / Product Poster

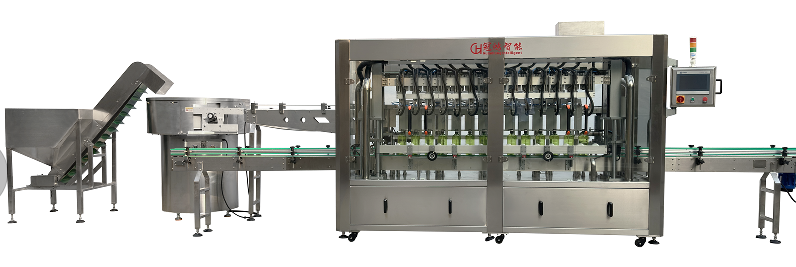

DOUBLE-HEADED FOLLOW-UP FILLING AND CAPPING LINE

Double head tracking servo filling machine

Technical parameters:

1. Number of filling head: 2 heads

2. Filling form: servo piston type

3. Filling capacity: 500ml~5000ml

4. Filling accuracy: ±1%

5. Program control: PLC+ touch screen

6. Material of contact parts: 304# stainless steel, PVC

7. Air pressure: 0.6-0.8MPa

8. Power: about 4KW

9. Voltage: AC220V 50/60Hz

10. Conveyor belt :82mm wide stainless steel chain belt, speed 0-15m/min

11.Conveyor motor: 750W frequency control motor

Double head tracking servo capping machine (Elevator cap sorter)

Technical parameters:

1. The electric sensor detects the bottle passing by, and the signal is transmitted to the servo motor to realize the transverse and longitudinal movement, and to catch the cap then starts capping.

2.Cap-taking and screw capping mechanism, servo motor;

3. Program control: PLC+ touch screen

4. Suitable for bottle Φ 30 - Φ 120 mm diameter, height 50-240 - mm;

5. Power: about 3KW

6. Voltage: AC220V 50/60Hz

7. Conveyor belt :82mm

PUMP HEAD COVER LOWER COVER SCREW CAP MACHINE

Technical Specifications:

1. Cap Head Count: 14

2. Suitable Bottle Shape: According to customer samples (different bottle shapes require replacement of molds)

3. Capping Form: Centrifugal disc capping

4. Feeding Cap Form: Servo-driven rotary feeding of molds to deliver caps to the capping head below

5. Capping Form: Servo-driven four-wheel clamping and capping with rotating head

6. Production Speed: 4000 bottles/hour (calculated based on 1Kg bottle)

7. Conveyor Belt: 114mm wide POM chain belt, speed 0-15 meters/minute, height from ground 850mm±25mm

8. Total Power Consumption: Approximately 14KW

9. Program Control: PLC with touch screen human-machine interface

10. Material: Stainless steel 304# for frame

11. Air Pressure: 0.6-0.8MPa

12. Power Supply: AC220V or 380V, 50/60HZ.

卡盘式灌装旋盖贴标一体机

6.适合瓶型:按客户样品(不同规格须更换部件及调节部件)

7.灌装容量:10ml-100ml

8.灌装形式:蠕动泵定量式灌装

9.理瓶形式:斜斗理瓶机理瓶(不同规格瓶须更换卡盘)

10.理盖形式:电磁振盘理盖(不同规格须更换振盘及导轨)

11.下瓶形式:机械手取瓶插入模具

12.下盖形式:机械手取盖下盖

13.旋盖形式:伺服驱动三爪旋盖头旋盖

13.测漏形式:抽真空后检测负压数值。

14.贴标形式:步进电机驱动出标,电动转瓶,毛刷抚标

15.生产速度: 20-30瓶/分钟

思源黑体预加载(勿删): GUANGDONG GUANHONG INTELLIGENT EQUIPMENT CO.,LTD.